50% OFF! Hot items selling fast—Grab them before they're gone!

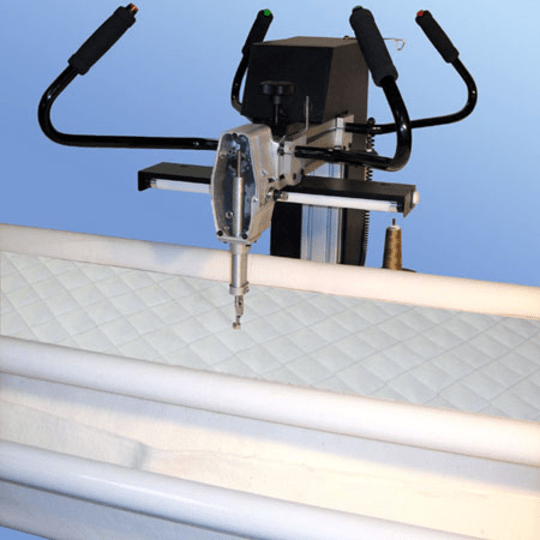

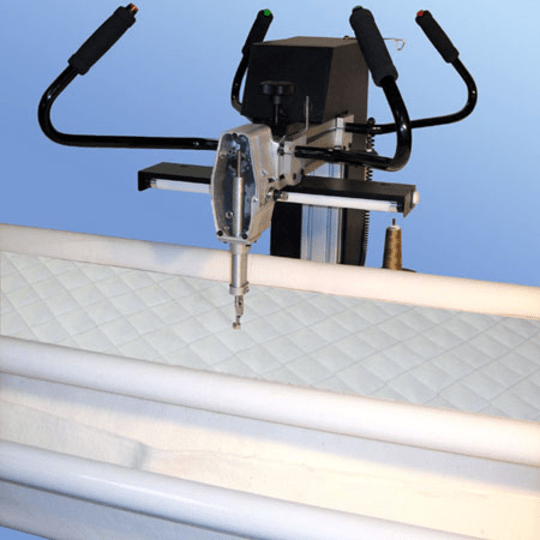

Applications

Features:

(“M” size bobbin in the 2611BQ)

Specifications:

| Motor: | 5/8 hp 4-pole brush DC |

| Speed: | 0-3000 spm |

| Frame: | 10 foot 1-1/2 in. 14 ga. steel square tubing |

| Capacity: | 1709Q:17 in. depth x 9 in. height 2611BQ:26 in. depth x 11 in. height |

| Voltage: | 115vac |

| Shipping Data: | Frame 290 lbs / 10′ length x 13″ width x 10″ height Machine 85lbs / 34″ length x 26″ width x 28″ height |

With so many options available for motors when we talk about replacing or buying a motor for our industrial sewing machine, there is one important point to keep always in mind “The Speed”. Regardless of brand or price, motors come in two different configurations:

Clutch motors operate at a fixed speed, typically between 1725 – 3450 rpm, depending on the type of machine. Servo Motors on the other hand are speed adjustable. The two major advantages of the Servo Motor are that you can control the speed of the motor and that the motor is completely silent when the pedal is not engaged.

Some other advantages of the Servo Motor include:

Most of our customers find that the sewing machine is much easier to control with a Servo motor because of the speed control. This is especially helpful for beginner sewers but also for projects that simply don’t require high speed stitching.